In the context of globalization and increasing competition in the global market, the role of logistics operators has become critically important for businesses. Efficient logistics allows companies to reduce costs, improve customer service quality, speed up product delivery, and adapt to changing market conditions. Logistics operators ensure the integration and coordination of various elements of the supply chain, enabling more flexible and faster responses to demand fluctuations. They play a key role in ensuring sustainable company growth, allowing businesses to focus on their core competencies.

In this article, we will explore the various types of logistics operators, their functions and responsibilities, as well as their classification based on the level of outsourcing. The article will examine the role of logistics operators in supply chain management and their significance for businesses. We will also discuss the current trends and challenges facing logistics operators, as well as the prospects for the industry's development in the context of a changing global market.

Basic Concepts and Classification of Logistics Operators

What Is a Logistics Operator?

A logistics operator is a specialized company that professionally manages all aspects of logistics activities, including the planning, implementation, and control of the efficient movement of goods and information from the point of production to the end consumer. These services may include transportation, warehousing, packaging, cargo handling, inventory management, customs clearance, and logistics consulting. Logistics operators act as intermediaries between the cargo owner and the end consumer, ensuring the efficient movement of goods and information at all stages of the supply chain. Operators can operate on local, national, or international levels, providing services of varying scale and complexity.

Functions and Responsibilities of Logistics Operators

The main functions of logistics operators include:

- Transportation. Organizing the transportation of goods using various modes of transport (road, rail, sea, air) to ensure timely delivery.

- Warehousing. Managing warehouse facilities for the storage of goods, including their receipt, placement, storage, and issuance.

- Inventory Management. Controlling inventory levels, optimizing their placement and replenishment to reduce costs and ensure uninterrupted supply.

- Packaging and Labeling. Preparing goods for transportation and sale, including packaging and applying appropriate labeling.

- Customs Clearance. Organizing customs procedures for importing and exporting goods, including the preparation of necessary documents and interaction with customs authorities.

- Consulting. Providing consulting services on logistics and supply chain management to optimize processes and increase efficiency.

Classification of Logistics Operators by Outsourcing Level

Definition of PL (Party Logistics)

The term PL (Party Logistics) refers to the level of outsourcing of logistics services. It reflects the degree of involvement of third-party companies in managing the logistics processes of an enterprise. The higher the number before PL, the more functions are outsourced to logistics providers.

Brief Overview of the Five Levels of Logistics Operators

- 1PL – Internal logistics, where the company independently manages all logistics operations without involving external providers.

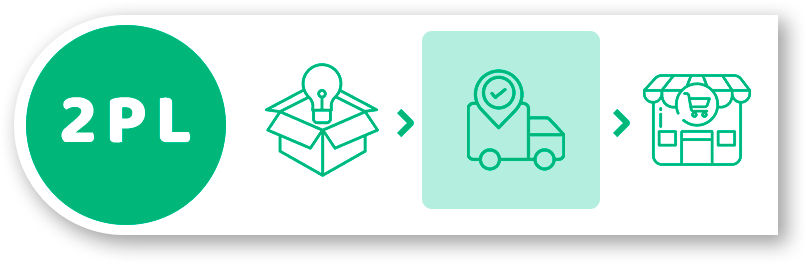

- 2PL – Partial outsourcing, where the company outsources specific logistics functions to specialized providers, usually transportation and warehousing.

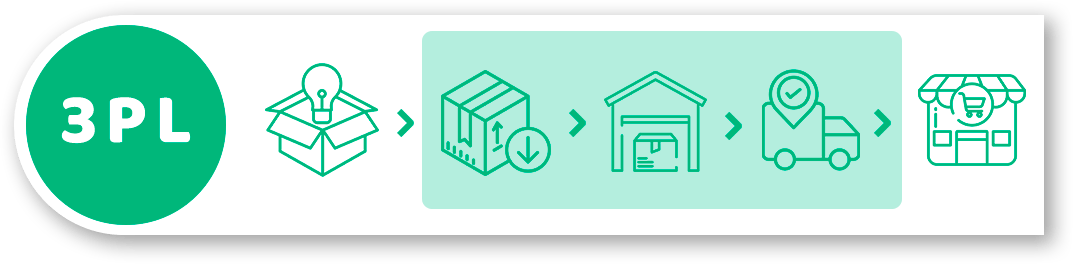

- 3PL – Comprehensive outsourcing, where the logistics operator takes over the execution of all or most logistics operations, including inventory management, transportation, and warehousing.

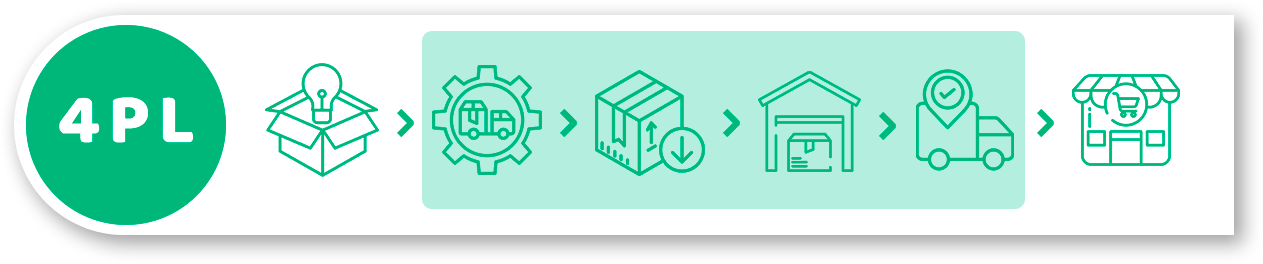

- 4PL – Integrated outsourcing, which involves managing the entire supply chain. The 4PL operator coordinates the work of several 3PL providers and handles the strategic management of logistics processes.

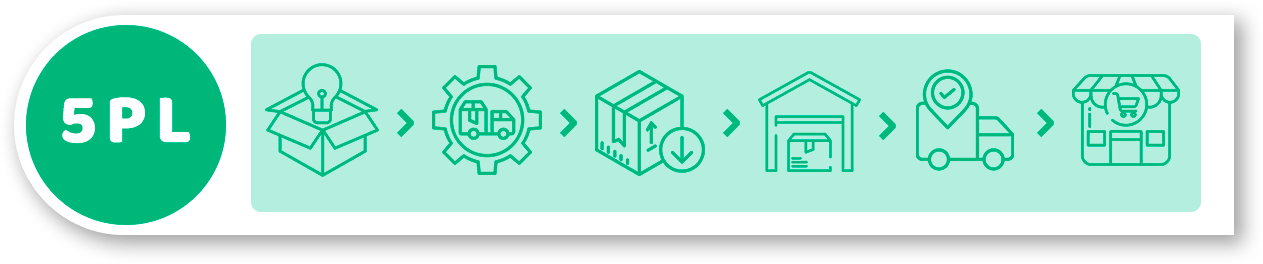

- 5PL – "Virtual" logistics, based on the use of modern IT technologies for managing global supply chains. 5PL operators specialize in the integration and optimization of logistics processes using data and analytics.

Types of Logistics Operators

Logistics operators are classified by outsourcing levels, starting with 1PL, where all logistics operations are handled by the manufacturer, to more complex models such as 5PL, which involve comprehensive digital solutions and integration of all elements of the supply chain. Each level of logistics operators has its own features and advantages, depending on the needs and goals of the business.

First Party Logistics (1PL)

Description of 1PL

First Party Logistics (1PL) represents a logistics level where the company fully manages all its logistics operations independently, without involving external providers. This includes managing all stages of the supply chain, from production and warehousing to transportation and delivery of goods to the end consumer.

Typically, the 1PL logistics model is used by companies with limited production and sales volumes that are focused on the local market. This allows them to maintain full control over logistics processes and minimize dependence on external factors.

Examples of 1PL Usage

Examples of 1PL usage include:

- Small manufacturing companies. Many small businesses and startups, such as local bakeries or farms, use the 1PL model to manage their logistics, as they serve local customers and do not require large-scale logistics services.

- Online stores with a limited range of products. Small online stores that manage their own warehouses and organize the delivery of goods independently may also use 1PL.

- Manufacturers with a closed production cycle. Companies engaged in processing and selling their products locally, such as building materials manufacturers, may use 1PL to optimize logistics processes.

Advantages and Disadvantages

Advantages:

- Full control. Companies retain full control over all logistics processes, allowing for flexible responses to changes in demand and market conditions.

- Cost savings on outsourcing. The absence of the need to pay third-party logistics providers for services can reduce costs, especially for small businesses.

- In-depth process knowledge. The ability to deeply understand and manage all aspects of logistics, which can improve service quality and customer satisfaction.

Disadvantages:

- Limited scalability. As the business grows and the volume of operations increases, the 1PL model may become less effective, requiring the company to invest in infrastructure development and hire additional staff.

- High initial investments. Creating and maintaining your own logistics infrastructure requires significant initial investments.

- Limited access to advanced technologies. Companies may miss opportunities to use modern technologies and innovations offered by specialized logistics providers.

Second Party Logistics (2PL)

Description of 2PL

Second Party Logistics (2PL) is a logistics model where a company engages specialized providers to perform specific logistics functions, such as transportation and warehousing. 2PL operators typically provide transportation and warehousing services using their own assets, such as fleets, containers, and warehouses. This model allows companies to partially delegate logistics operations while maintaining control over the strategic aspects of supply chain management.

Service Specifications and Examples

Service specifications of 2PL:

- Transportation. 2PL operators offer transportation services for goods using various modes of transport, including road, rail, sea, and air.

- Warehousing. Organization of goods storage in the provider's own warehouses, allowing the company to avoid the costs of maintaining its own storage facilities.

- Loading and Unloading Operations. Provision of loading and unloading services, which is particularly important for companies with large or bulky cargo.

Examples of 2PL usage:

- Transportation companies. Many transportation companies, such as FedEx and DHL, offer 2PL services, ensuring the transportation of goods for their clients.

- Warehouse operators. Companies that provide warehouse space for storing goods, such as logistics parks and terminals.

- Marine and rail carriers. The use of 2PL services to organize international and interregional transportation of large cargoes.

Advantages and Disadvantages

Advantages:

- Infrastructure savings. Companies can reduce capital expenditures associated with purchasing and maintaining transportation vehicles and warehouses.

- Access to specialized services. 2PL operators possess significant expertise and resources in transportation and warehousing, which enhances the efficiency of logistics processes.

- Flexibility. Companies can choose 2PL providers based on their current needs, adapting logistics to specific tasks.

Disadvantages:

- Limited control. Companies must rely on external partners to perform key logistics functions, which may reduce the level of control over service quality.

- Dependence on providers. The success of a logistics operation depends on the reliability and professionalism of the 2PL operator, increasing risks if there are deficiencies in their performance.

- Limited scalability. The ability to expand services may be constrained by the provider's logistics infrastructure, potentially requiring additional partners as operations grow.

Third Party Logistics (3PL)

Description of 3PL

Third Party Logistics (3PL) is a logistics model where a company outsources most or all of its logistics operations to a third-party provider. 3PL operators provide comprehensive management of logistics processes, including transportation, warehousing, inventory management, order fulfillment, and logistics support. This allows companies to focus on their core business processes, leaving logistics operations to professionals.

Main Services and Examples

Main services of 3PL:

- Transportation. 3PL providers organize the transportation of goods using various modes of transport, including road, rail, sea, and air, optimizing routes and costs.

- Warehousing. Management of warehousing operations, including receipt, storage, picking, and distribution of goods, as well as inventory management.

- Order Fulfillment. Processing orders, picking, packing, and shipping goods to end consumers, including reverse logistics services.

- Information Support. Providing access to logistics management systems (WMS, TMS) and analytical data to improve visibility and control.

Examples of 3PL usage:

- FedEx and DHL. Leading international logistics companies that provide 3PL services, including transportation, warehousing, and order fulfillment for various industries.

- Amazon Fulfillment. A platform for sellers using Amazon's services for storage and delivery of goods, allowing them to focus on sales rather than logistics.

Advantages and Disadvantages

Advantages:

- Economy of scale. 3PL providers can offer economies of scale, which reduces logistics costs through process optimization and the use of their own infrastructure.

- Specialized expertise. Companies gain access to professional skills and technologies, enhancing the efficiency of logistics operations.

- Flexibility and adaptability. The ability to quickly adapt to changes in demand and market conditions by utilizing 3PL provider resources.

Disadvantages:

- Limited control. Outsourcing logistics functions can lead to a loss of control over certain aspects of logistics, requiring careful selection of the provider.

- Dependence on a third party. The business becomes dependent on the efficiency and reliability of the 3PL provider, which can affect the overall level of service.

- Integration challenges. Integrating information systems and processes with a 3PL provider can be a complex task, especially for large companies.

Role in the Supply Chain

3PL providers play a key role in the supply chain by ensuring the integration and coordination of various logistics functions. They act as intermediaries between manufacturers, distributors, and end consumers, optimizing processes and reducing costs. 3PL providers help companies focus on their strategic objectives while improving the quality and speed of product delivery to market.

Fourth Party Logistics (4PL)

Description of 4PL

Fourth Party Logistics (4PL) represents a logistics level where the provider assumes full management of the client’s entire supply chain, including strategic planning, integration, and coordination of all logistics processes. 4PL providers act as strategic partners, offering comprehensive management of logistics infrastructure and coordination with other logistics operators, such as 3PL.

Supply Chain Integration and Management

4PL providers are responsible for the integration and coordination of all logistics operations for their clients, ensuring:

- The development and implementation of long-term supply chain management strategies, including the optimization of routes and transportation methods.

- Management of all aspects of supply, including coordination with suppliers, transportation companies, and distributors.

- Utilization of analytical data to improve the efficiency of logistics processes and reduce costs.

- Implementation of advanced technologies and methods to enhance supply chain management.

Advantages and Disadvantages

Advantages:

- Comprehensive management. 4PL providers offer full management of the entire logistics infrastructure, allowing clients to focus on their core business processes.

- Advanced technologies and analytics are used to optimize all aspects of the supply chain.

- 4PL providers act as strategic partners, helping companies achieve their long-term goals.

Disadvantages:

- High cost. 4PL services may be more expensive compared to 3PL due to the more comprehensive level of management.

- Dependence on the provider. Fully outsourcing logistics management can increase a company’s reliance on the efficiency of the 4PL partner.

- Integrating all processes and systems with a 4PL provider can require significant effort and resources.

Fifth Party Logistics (5PL)

Description of 5PL

Fifth Party Logistics (5PL) represents the highest level of logistics outsourcing, which involves the use of advanced technologies and innovative solutions to manage and optimize all aspects of the supply chain. 5PL providers integrate digital technologies such as artificial intelligence, big data, and the Internet of Things (IoT) to create fully automated and optimized logistics processes.

Use of Technologies and Innovations

5PL providers actively use advanced technologies to improve supply chain management:

- Artificial Intelligence (AI). Used for demand forecasting, route optimization, and inventory management.

- Big Data. Analysis of large volumes of data to enhance the efficiency and accuracy of logistics processes.

- Ensuring transparency and control over the movement of goods in real-time.

- Implementation of robotic systems to perform routine operations such as packing and loading.

Advantages and Disadvantages

Advantages:

- Advanced solutions. 5PL providers offer the most modern and innovative logistics management solutions.

- Ensuring maximum automation and efficiency of all logistics processes.

- Providing full transparency and control over all aspects of the supply chain.

Disadvantages:

- The use of advanced technologies may require significant investments.

- The implementation and integration of new technologies into existing processes can be a challenging task.

- Companies become dependent on technological infrastructure and data.

Examples in E-commerce

Alibaba – a Chinese e-commerce platform utilizing 5PL to manage global supply chains and ensure fast order fulfillment.

OZON – a Russian company actively adopting the 5PL approach, including the use of advanced technologies and automation to manage complex logistics processes, ensuring efficient order fulfillment and supply chain optimization.

Amazon – one of the world's largest e-commerce leaders, employing a 5PL approach to integrate logistics processes, including advanced technologies such as automation and artificial intelligence, to manage global supply chains.

Examples of 5PL Operators

Maersk (Denmark) – provides global supply chain solutions with a focus on digital integration and sustainable practices.

SNECI (France) – specializes in supply chain optimization and management of production processes using advanced technologies.

XPO (USA) – focuses on supply chain management using advanced technologies and analytics to enhance efficiency.

UPS Supply Chain Solutions (USA) – offers integrated logistics solutions, including global supply chain management, data analytics, and technology.

Agility (Kuwait) – a global logistics company specializing in 5PL services, including supply chain management using digital technologies, process automation, and strategic planning to improve efficiency and reduce costs.

Kuehne + Nagel (Switzerland) – one of the world's leading logistics operators, offering comprehensive solutions for supply chain management.

DHL Supply Chain (Germany) – uses innovative solutions to optimize supply chains and offers comprehensive logistics services.

DB Schenker (Germany) – utilizes innovative technologies and a global network to manage logistics processes and optimize supply chains.

CEVA Logistics (France) – provides 5PL services with a focus on managing complex logistics processes and innovative technologies.

Comparison and Selection of a Logistics Operator

Selecting a logistics operator is a strategic decision that can significantly impact a company's efficiency and competitiveness. Understanding the key criteria for selection and the advantages of various levels of logistics operators allows companies to optimally organize their logistics processes and achieve their business goals.

Criteria for Selecting a Logistics Operator

Strategic Business Goals

The choice of a logistics operator should align with the company's long-term strategic goals. If the company is aiming for rapid expansion into new markets, a 3PL or 4PL operator that offers comprehensive management and flexibility may be required. For companies focused on innovation and the implementation of modern technologies, 5PL might be the optimal solution due to its high level of automation and IT utilization.

Scale and Complexity of Operations

The scale and complexity of operations play a key role in selecting a logistics operator. Small companies with a local reach and simple logistics needs can successfully manage logistics independently using 1PL or 2PL. However, companies with a global presence, complex supply chains, and high service requirements will likely prefer 3PL, 4PL, or 5PL services to manage complex operations and ensure reliability.

Technological Requirements

Modern logistics is increasingly dependent on technology. Companies that place great importance on the use of technologies such as AI, IoT, and Big Data should consider operators capable of integrating these technologies into logistics processes. This is particularly relevant for 5PL, where the use of advanced technologies is a key element. 4PL can also be a good option for those seeking integration and coordination in the supply chain using technology.

Advantages and Disadvantages of Different PL Levels

Comparison of 1PL, 2PL, 3PL, 4PL, and 5PL

| Level | Advantages | Disadvantages |

|---|---|---|

| 1PL | Full control, cost savings on outsourcing, in-depth process knowledge | Limited scalability, high initial investments, limited access to technology |

| 2PL | Infrastructure savings, access to specialized services, flexibility | Limited control, dependence on providers, limited scalability |

| 3PL | Economy of scale, specialized expertise, flexibility and adaptability | Limited control, dependence on third parties, integration challenges |

| 4PL | Comprehensive management, process optimization, strategic partnership | High cost, dependence on the provider, integration challenges |

| 5PL | Advanced solutions, high degree of automation, transparency and control | High costs, implementation complexity, dependence on technology |

Selection Based on Business Goals and Resources

1PL and 2PL – suitable for small companies that prioritize control and cost savings. Companies with a local reach and simple logistics needs can successfully use these levels.

3PL – an excellent choice for medium-sized companies and large enterprises looking to reduce costs and improve the quality of logistics operations. It is suitable for companies that need comprehensive services but do not want to completely relinquish control.

4PL – ideal for large corporations with global supply chains seeking strategic partnerships and full integration of all logistics processes.

5PL – perfect for innovative companies willing to invest in advanced technologies to achieve maximum efficiency and automation. It is particularly relevant for companies in the e-commerce and high-tech sectors.

Trends and Future Prospects for Logistics Operators

Modern logistics is constantly evolving, and logistics operators must adapt to new market demands and technologies to remain competitive. Key areas of development include technological innovations, globalization, and environmental sustainability. Let's take a closer look at these aspects and their impact on logistics operators.

Technological Innovations in Logistics

The Role of IT and Automation

Information technology and automation play a crucial role in transforming logistics. Modern technologies significantly enhance the efficiency and accuracy of logistics operations. Some of these technologies include:

- Warehouse Management Systems (WMS) and Transportation Management Systems (TMS). These systems automate inventory and transportation management processes, reducing costs and increasing operational accuracy.

- Artificial Intelligence (AI). AI is used for demand forecasting, route optimization, and improving operational efficiency. For example, AI algorithms can analyze large volumes of data and provide recommendations for improving logistics processes.

- IoT devices allow real-time tracking of goods movement, providing full transparency and control over the logistics chain. This enables faster response to changes and potential issues.

- The use of robots and automated systems in warehouses can significantly reduce labor costs and increase order processing speed.

Impact on Efficiency and Speed

Technological innovations make logistics faster and more efficient. Process automation reduces errors and increases the speed of operations. For example, the implementation of robotic systems in warehouses allows more orders to be processed in less time, improving customer service quality.

Technologies also help logistics operators reduce costs by optimizing routes and resource usage. This allows companies not only to lower prices for their services but also to enhance quality, which is especially important in an increasingly competitive environment.

Globalization and International Supply Chains

The Impact of Globalization on Logistics

Globalization has led to the expansion of international supply chains, requiring logistics operators to adapt to more complex and longer routes. Global companies are increasingly relocating production to countries with lower costs, creating new challenges for logistics.

Globalization also intensifies competition as companies strive to optimize their supply chains to increase efficiency. This drives the demand for comprehensive logistics solutions, which can be offered by 3PL and 4PL operators.

Adapting Logistics Operators to New Challenges

Logistics operators are adapting to the challenges of globalization through:

- Investing in global infrastructure, which allows for more efficient management of international goods flows.

- Deepening cooperation to create integrated supply chains that ensure more effective resource management.

- Implementing IT systems that optimize routes and inventory management on a global scale, reducing costs and increasing delivery speed.

Environmental and Sustainable Practices

Sustainable Development and Logistics

Environmental sustainability is becoming an important aspect of logistics as companies and consumers increasingly focus on environmental responsibility. Logistics operators are striving to minimize negative environmental impacts by implementing sustainable practices.

The Role of Logistics Operators in Environmental Responsibility

Logistics operators can play a key role in achieving sustainable development through:

- The use of environmentally friendly modes of transport, such as electric or hybrid trucks.

- The use of technologies to optimize routes and reduce fuel consumption.

- The implementation of waste management and packaging recycling programs.

- The transition to renewable energy sources.

Conclusion

Modern logistics faces numerous challenges, including the need to adapt to globalization, implement technological innovations, and ensure environmental sustainability. Logistics operators who can effectively meet these challenges gain a significant competitive advantage. The right choice of logistics operator plays a key role in a company's success. Companies must carefully assess their needs and choose an operator who can ensure not only high-quality service but also alignment with the business's strategic goals and values.

The future prospects of the logistics industry are tied to further technological integration, increased demand for sustainable practices, and the development of global supply chains. Logistics operators who can adapt to these changes will play a key role in shaping the industry's future. As technology continues to advance and logistics processes become more complex, the importance of professional logistics operators will only increase.